|

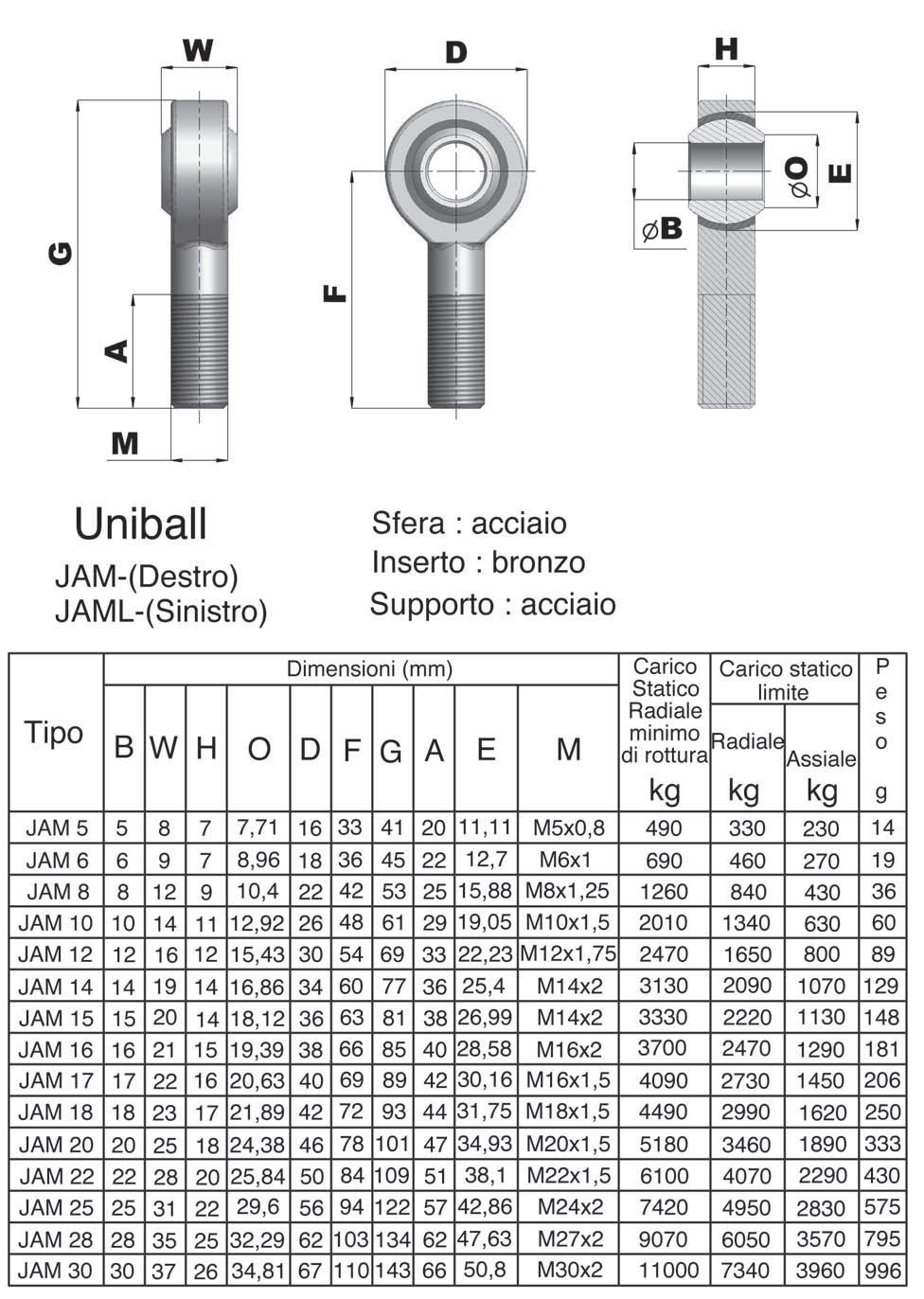

Tipo Type Typ |

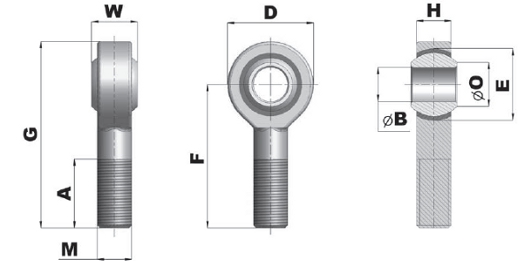

Dimensioni – Dimensions– Abmessungen(mm) |

Peso Weight |

CSL (kg) |

CSR (kg)

|

||||||||||||||

|

B

|

W

|

H

|

O

|

D

|

F

|

G

|

A

|

E

|

M

|

|||||||||

|

Gewicht |

Rad |

Ass |

||||||||||||||||

|

JAM 5 |

5 |

8 |

7 |

7,71 |

16 |

33 |

41 |

20 |

11,11 |

M5x0,8 |

14 g |

330 |

230 |

490 |

||||

|

JAM 6 |

6 |

9 |

7 |

8,96 |

18 |

36 |

45 |

22 |

12,70 |

M6x1 |

19 g |

460 |

270 |

690 |

||||

|

JAM 8 |

8 |

12 |

9 |

10,40 |

22 |

42 |

53 |

25 |

15,88 |

M8x1,25 |

36 g |

840 |

430 |

1260 |

||||

|

JAM 10 |

10 |

14 |

11 |

12,92 |

26 |

48 |

63 |

29 |

19,05 |

M10x1,5 |

60 g |

1340 |

630 |

2010 |

||||

|

JAM 12 |

12 |

16 |

12 |

15,43 |

30 |

54 |

69 |

33 |

22,23 |

M12x1,75 |

89 g |

1650 |

800 |

2470 |

||||

|

JAM 14 |

14 |

19 |

14 |

16,86 |

34 |

60 |

77 |

36 |

24,40 |

M14x2 |

129 g |

2090 |

1070 |

3130 |

||||

|

JAM 15 |

15 |

20 |

14 |

18,12 |

36 |

63 |

81 |

38 |

26,99 |

M14x2 |

148 g |

2220 |

1130 |

3330 |

||||

|

JAM 16 |

16 |

21 |

15 |

19,39 |

28 |

66 |

85 |

40 |

28,58 |

M16x2 |

181 g |

2470 |

1290 |

3700 |

||||

|

JAM 17 |

17 |

22 |

16 |

20,63 |

40 |

69 |

89 |

42 |

30,16 |

M16x1,5 |

206 g |

2730 |

1450 |

4090 |

||||

|

JAM 18 |

18 |

23 |

17 |

21,89 |

42 |

72 |

93 |

44 |

21,75 |

M18x1,5 |

250 g |

2990 |

1620 |

4490 |

||||

|

JAM 20 |

20 |

25 |

18 |

24,38 |

46 |

78 |

101 |

47 |

34,93 |

M20x1,5 |

333 g |

3460 |

1890 |

5180 |

||||

|

JAM 22 |

22 |

28 |

20 |

25,84 |

50 |

84 |

109 |

51 |

38,10 |

M22x1,5 |

430 g |

4070 |

2290 |

6100 |

||||

|

JAM 25 |

25 |

31 |

22 |

29,60 |

56 |

94 |

122 |

57 |

42,86 |

M24x2 |

575 g |

4950 |

2830 |

7420 |

||||

|

JAM 28 |

28 |

35 |

25 |

32,29 |

62 |

103 |

134 |

62 |

47,63 |

M27x2 |

795 g |

6050 |

3570 |

9070 |

||||

|

JAM 30 |

30 |

37 |

26 |

34,81 |

67 |

110 |

143 |

66 |

50,80 |

M30x2 |

996 g |

7340 |

3960 |

11000 |

||||

|

CSL

|

Carico statico limite (Radiale/Assiale) Static limit load (Radial/Axial) Statische Grenzlast (Radial/Axial) |

CSR

|

Carico statico radiale minimo di rottura Minimum radial static breaking load Minimale radiale statische Bruchlast |

|||||||||||||||

![]() Click to enlarge image

Click to enlarge image

| Sphere / Support | Steel |

| Inlay | Bronze |

| Uniball JAM | Right |

| Uniball JAML | Left |

General precautions to be followed in the installation and assembly of load cells: