Gicam weight indicators are weight indicator devices connected to load cells. We have multifunction displayers for weighing and dosing, for bridge weighing, with load limiter. Portable displayers are available in comfortable briefcases. We have panel mounting, portable, DIN and OMEGA bar mounts, analog indicators and touch screens indicators. IP65 products are available with dust protection. Gicam indicators support industrial communication protocols like PROFIBUS, PROFINET, MODBUS and more.

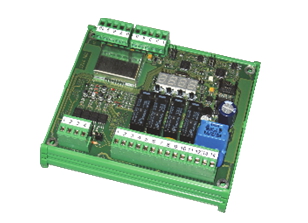

LOAD LIMITER for load cells

![]() Click to enlarge image

Click to enlarge image

| Power supply | 10 - 30 VDC, protected against polarity inversion. Protection with resettable fuse | |

| Max power consumption | 6 W | |

| Operating temperature | -10 / +50 °C (14 / 122 °F) Humidity Maximum 85% non-condensing | |

| Display | 4-digit numeric red LED with 7 segments (h 7 mm) | |

| Keyboard | 4 mechanic keys | |

| Linearity | < 0.01% of full scale | |

| Internal resolution | 24 bit | |

| Weight resolution | Up to 10,000 divisions of load | |

| Measuring range | From -3.9 mV/V to +3.9 mV/V | |

| Zero / FS Calibration | Automatic (theoretical) or executable through buttons | |

| Logical output alarm | 4 relay outputs (24 V DC one changeover contact), Power supply contacts and board must be the same | |

| Serial port | 2 RS232 programming module | |

| Max. cable length | 15 m | |

| Serial protocols | CANOpen port (optional) Data transmission and card programming | |

| Conforms to standards | Compliance to EMC norms: EN61000-6-2, EN61000-6-3, Compliance electric safety: EN 61010-1, EN13849-1 | |

General precautions to be followed in the installation and assembly of load cells: